Watching a 3-D printer crank out its product, layer upon layer, can be like watching paint dry.

But a radical new process promises 3-D printing speeds 25 to 100 times faster — and it’s more like watching a creature emerge from primordial ooze.

Carbon3D has rolled out a process it calls “Continuous Liquid Interface Production” — or CLIP. The company announced the new process with both a TED Talk and paper published in the journal Science this week.

“We think that popular 3-D printing is actually misnamed — it’s really just 2-D printing over and over again,” Joseph DeSimone, a chemistry professor in North Carolina, and one of Carbon3D’s co-founders, told the Washington Post.

Diabetes Breakthrough: Scientists Coax Human Stem Cells Into Making Insulin

That’s because Current 3-D printing methods slowly build objects layer-by-layer. Not only does that take forever, it also means the finished object is going to have structural weaknesses built in — the layers can slip and slide against each other.

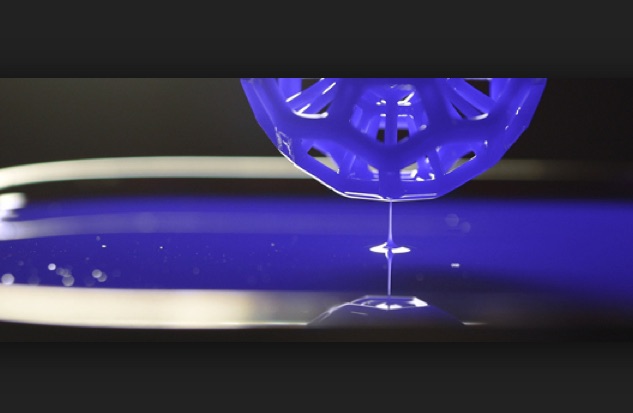

CLIP creates a solid object. It uses light and oxygen to turn a mechanical printing process into a photochemical one. This new process fires bursts of light and oxygen through a tiny window — only microns across — the size of two or human cells.

The light hardens resin, the oxygen keeps it from hardening. A careful, high-speed balance between when the printer uses light and when it uses oxygen allows it to craft intricately detailed objects. On top of that, the finished objects are all in one piece, not simply stacked layers that could result in tiny sharp edges.

And, as the company video shows, the finished object appear to rise out of a pool of goo.

(WATCH the video, showing the creation of a mini Eiffel Tower, below)

SHARE the Story (below) / Photo credit: Carbon3D