When it comes to explaining Roman engineering, people looking to demonstrate their genius have a variety of use cases, but the secret to why their concrete has remained when even modern buildings crumble after just a few years of disuse has eluded scientists.

However at MIT, scientists have cracked their concrete code to show that Roman concrete was self-repairing—it could naturally close cracks in as little as 2 weeks.

If one were to go to the small city of Pozzuoli today, what the classical Romans called Peotoli, one would find two remarkable structures—an amphitheater, and a covered marketplace called Rione Terra. However another mark which Pozzuoli left on the Roman world is called “pozzolanic material” referring to a hotspot underneath a nearby hill that created a mineral mosaic over thousands of years.

It created a kind of volcanic ash rich in lime and calcium, which form chunks of white material called lime clasts. Ancient recipes dictate this ash was an important ingredient, but modern analysis looking at the presence of the lime clasts in the ash has essentially written it off as “low-quality control.”

“The idea that the presence of these lime clasts was simply attributed to low quality control always bothered me,” said MIT professor of civil and environmental engineering, Admir Masic.

“If the Romans put so much effort into making an outstanding construction material, following all of the detailed recipes that had been optimized over the course of many centuries, why would they put so little effort into ensuring the production of a well-mixed final product? There has to be more to this story.”

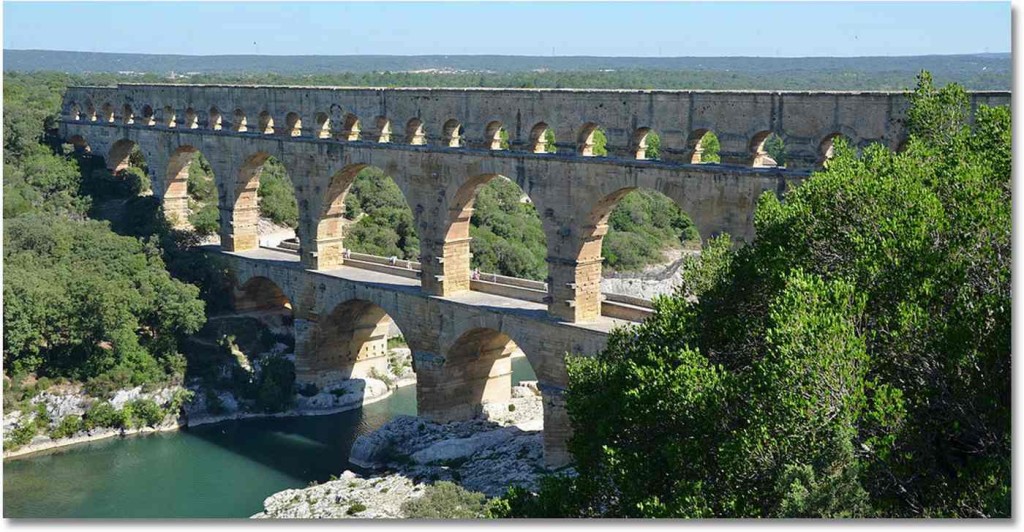

Indeed, the Romans did things with concrete that modern societies haven’t—just look at the Pantheon in Rome which still has the world’s largest unreinforced concrete dome. Aqueducts built to water the city literally still do, 2,000 years and sometimes more after they were built.

SIMILAR: 2,000-Year-Old Roman Road Uncovered in British Field is Like No Other–And of ‘Global Importance’

As if anyone who’s witnessed the timeless glory of Roman architecture today would be surprised, it turns out that the lime clasts were there on purpose, because they provide a self-healing capacity to Roman concrete, allowing their structures to last for thousands of years.

It was once assumed that lime was added to concrete with water to create a paste in a process called slaking, but by using spectroscopic imaging, Masic and his colleagues at MIT, and elsewhere in Switzerland and Italy, have determined that the Romans heated the lime ash to high temperatures to create what is known today as “quicklime.”

“The benefits of hot mixing are twofold,” Masic says. “First, when the overall concrete is heated to high temperatures, it allows chemistries that are not possible if you only used slaked lime, producing high-temperature-associated compounds that would not otherwise form. Second, this increased temperature significantly reduces curing and setting times since all the reactions are accelerated, allowing for much faster construction.”

MORE ROMAN NEWS: Making Wine the Way the Romans Did: These Wineries are Cutting The Additives

In such concrete as this, cracks that form allow the easy travel of the lime clasts into open space which, when coming in contact with water, seal and close the cracks. The team mixed their own Roman concrete and it took only 2 weeks for a deliberately inflicted crack to close.

By contrast a contemporary concrete block was made without quicklime and it never repaired itself.

As a result, the team are working to commercialize this as self-healing Roman concrete in order to reduce the 8% of global emissions attributed to the manufacture and laying of concrete in cities.

SHARE This Brain Blast From The Past With Your Friends…