An Indian initiative is utilizing a scientific technique known as spectroscopy to prove the authenticity of traditional, handwoven silken garments over forgeries.

Often making headlines in the study of planets and nebulae in our galaxy, the spectroscopy device allows for quick and indisputable textile analysis at the molecular level—giving traditional weavers the authority to market their products with the premium their generational knowledge and renowned abilities deserve.

This unique story comes by way of Bengaluru, where two men working at the cutting edge of technology have set out to help a centuries-old technology.

For the sake of the unknowing, in the Indian fashion world, the Banarasi saree is the most valuable of its kind, and among those, the Kadwa saree, translating literally to “difficult,” stands as the most supreme example of the Indian silk-weaving artform.

A single Kadwa saree can take months to finish. They involve weaving the intricate patterns and images into each line of the handloom rather than stitching or embroidering them on after the fact. Done by hand on traditional looms, filaments of gold or silver are sometimes woven in, and unlike other forms of Banarasi sarees, there are no loose threads on the reverse face.

Vijaya Krishnappa and Ramki Kodipady—the former an software engineer, and the later and electronics engineer—met in 2020 and shared a unique sense of injustice: that weavers of Kadwa sarees were getting pushed out of the market by counterfeiters selling inferior knock-offs.

At the same time, each man on his own saw fast fashion and synthetic textiles as a major contributor of landfill waste, and sought to use technology to alleviate some of the problem.

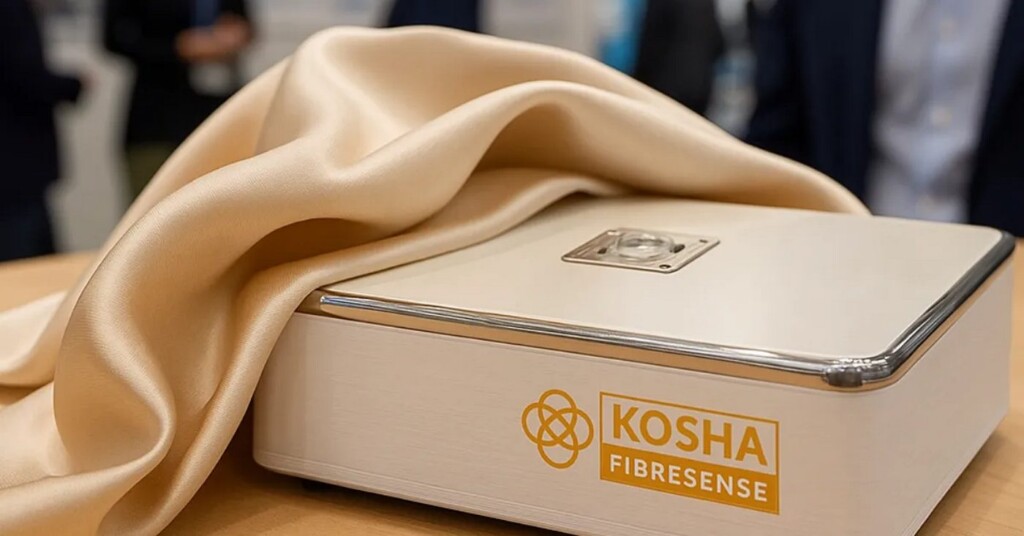

They launched the start-up KOSHA.ai to market their first flagship device they saw as a solution to both problems.

Called “WeaveSENSE” the book-sized device uses near-infrared spectroscopy paired with AI-driven chemometric modelling to identify the fiber composition of the fabric placed atop it.

WeaveSENSE first bombards the fabric with near-infrared electromagnetic waves, then records how that fabric—and more importantly the materials made to construct it—react to the waves.

The device captures loom-specific signatures, weaving rhythms, and manufacturing timestamps which are together converted into “a tamper-proof digital provenance trail.” A QR code on the final product allows customers to view real-time clips of how their saree or fabric was woven.

“We saw Kadwa sarees being sold for nearly 50,000 [rupees, approximately $553] but the artisans who wove them struggled to earn even a fraction of that,” Krishnappa told the Better India. “Weavers told us that customers simply didn’t believe them anymore. And without trust, their livelihood collapsed.”

A BETTER INDIA: Man Revives Iconic Indian Lake by Converting Lake Weed Infestation into Organic Fertilizer Business

Krishnappa and Kodipady were satisfied with their attempt to prove authenticity, and turned their attention to how their new desk-top technology could aid in textile recycling.

Through an analysis of the light reflected off the material, WeaveSENSE can reveal exactly how the material was made, and how expensive it should be according to that method. The same tech—near-infrared spectroscopy—needed just a little tweak to become FibreSENSE, a parallel device designed specifically to detect with extreme detail the exact material composition of a fiber—either from a finished cloth or as yarn.

“Every fiber speaks a different language,” Kodipady told the Better India. “FibreSENSE is the interpreter. In seconds, it tells you whether a fabric is cotton, polyester, wool, silk, viscose, or a blend, and in what proportion.”

ALSO CHECK OUT: Officer Converts Old Train Car into ‘Hospital on Wheels’ to Bring Healthcare to Remote India

Non-destructive, cost-effective, and immediate, FibreSENSE would allow textile workers to do with 100% accuracy what they used to do just by sense of touch and an educated guess—to determine what kind of thread, yarn, or cloth they were actually using.

“FibreSENSE helps us supply exactly what recyclers or paper-makers need, like 80 to 90 percent polyester, or specific cotton–poly ratios for felt. It has made us more accurate and more confident in what we do,” said Gopika Santhosh at Green Worms Waste Management, in testimony of the project.

COOL USE OF SPECTROSCOPY: Greatest Spectroscope Ever Built Can Tell What 2,400 Cosmic Objects Are Made of Every 20 Mins.

It allowed recyclers and manufacturers to know exactly what they were holding, and therefore exactly what they could do with it. To date, this has saved some 22,000 pounds of textiles from being thrown away due to this confusion. For the saree makers, some 1,200 are now represented by merchants empowered by WeaveSENSE to demand the premium their weavers’ skills demand.

More impact and testimony regarding KOSHA’s products can be found at the Better India.

SHARE This Great Invention Solving Two Problems With A Single Small Box…