Scientists believe they’ve found a way to make plastics more durable and biodegradable by adding bacterial spores that have been put through evolutionary rigors.

This kind of “living plastic” can break down in about five months without the necessary addition of any other microbes.

Researchers led by scientists at the University of California San Diego (UCSD) created this living plastic in the form of thermoplastic polyurethane (TPU), a soft but durable commercial plastic used in footwear, floor mats, cushions, and memory foam.

They explained that the material is filled with bacterial spores that, when exposed to nutrients present in compost, germinate and break it down at the end of its life cycle.

The biodegradable TPU was made with bacterial spores from a strain of Bacillus subtilis that has the ability to break down plastic polymer materials.

“It’s an inherent property of these bacteria,” said study co-senior author Professor Jon Pokorski, of UC San Diego Jacobs School of Engineering. “We took a few strains and evaluated their ability to use TPUs as a sole carbon source, then picked the one that grew the best.”

The research team used bacterial spores, a dormant form of bacteria, due to their resistance to harsh environmental conditions.

Pokorski explained that unlike fungal spores, which serve a reproductive role, bacterial spores have a protective “protein shield” that enables bacteria to survive while in a vegetative state.

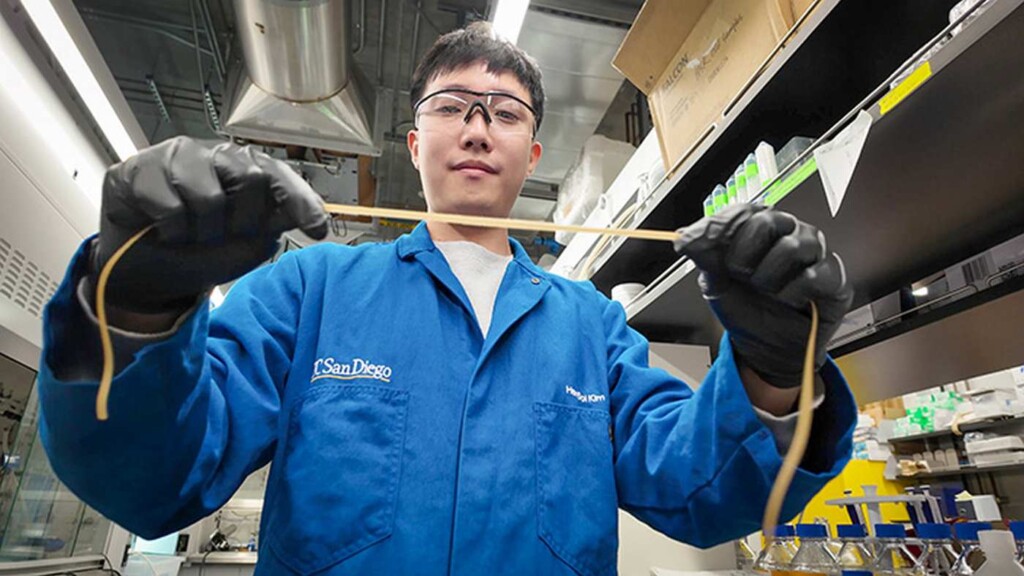

To make the biodegradable plastic, the researchers fed Bacillus subtilis spores and TPU pellets into a plastic extruder. The ingredients were mixed and melted at over 200°F, then extruded as thin strips of plastic.

To assess the material’s biodegradability, the strips were placed in both microbially active and sterile compost environments. Prof Pokorski said the compost setups were maintained at around 100°F with a relative humidity ranging from 44 to 55%.

Water and other nutrients in the compost triggered germination of the spores within the plastic strips, which reached 90% degradation within five months.

“What’s remarkable is that our material breaks down even without the presence of additional microbes. Chances are, most of these plastics will likely not end up in microbially rich composting facilities,” said Professor Pokorski.

SOLVING PROBLEMS: Indian Startup Uses Rice Crop Waste to Make Biodegradable Foam Packaging–Instead of Burning it

“So this ability to self-degrade in a microbe-free environment makes our technology more versatile.”

Although the researchers still need to study what gets left behind after the material degrades, they believe that any lingering bacterial spores are likely harmless.

Pokorski explained that Bacillus subtilis is a strain used in probiotics that’s generally regarded as safe to humans and animals and can even be beneficial to plant health.

For the study, published in the journal Nature Communications, the bacterial spores were evolutionary nudged to adapt to the hot temperatures necessary for manufacturing the TPU. The strains that survive this process are then isolated and put through the cycle again.

OTHER PLASTICS THAT BREAKDOWN: Scientists Create World’s First Truly Biodegradable Single-use Plastic That ‘Eats Itself’ in Just 2 Weeks

“We continually evolved the cells over and over again until we arrived at a strain that is optimized to tolerate the heat,” said study co-senior author Dr. Adam Feist, a bioengineering research scientist at UCSD. “It’s amazing how well this process of bacterial evolution and selection worked for this purpose.”

He said the spores also serve as a strengthening filler, similar to how rebar reinforces concrete, resulting in a TPU variant with enhanced mechanical properties—requiring more force to break and showing greater stretchability.

MORE INNOVATIVE MATERIALS: Scientists Create Biodegradable Batteries That Can Be Buried in Soil After Use

“This is great because the addition of spores pushes the mechanical properties beyond known limitations where there was previously a trade off between tensile strength and stretchability,” said Pokorski.

The research team is now working on optimizing the approach for use on an industrial scale.

“There are many different kinds of commercial plastics that end up in the environment – TPU is just one of them.” said Dr. Feist. “One of our next steps is to broaden the scope of biodegradable materials we can make with this technology.”

More markets looking to utilize this, and other forms of similar technology, the question will always be how expensive it is to make. Plastics are mass-produced, and anything that breaks down will have to be priced at an acceptable mark-up and produced in bulk for this and other biodegradable plastics to catch on.

SHARE This Great Invention With Your Friends…

I don’t think I would want this kind of plastic in my footwear, floor mats, cushions, and memory foam, that breaks down in 5 months. How are they going to control this? This material will be useful in other products that are usually single use, but not… things you use for a much longer time. It would be better to get rid of plastic all together (since it is after all, made from petroleum) and use a more environmentally friendly substance.

These articles, while very interesting, are often too short and don’t give enough information.