Snow accumulation atop solar panels causes energy losses of between 5% and 15% every Winter in northern climates around the world, with some heavy snowfall even leading to mechanical loads that damage PV modules.

Keeping solar panels snow-free has been a costly and inefficient proposition—until now.

Materials and engineering scientists at the University of Toledo have developed an ingenious solution that is winning awards and satisfying the demand of 150 solar plant operators in their latest pilot tests.

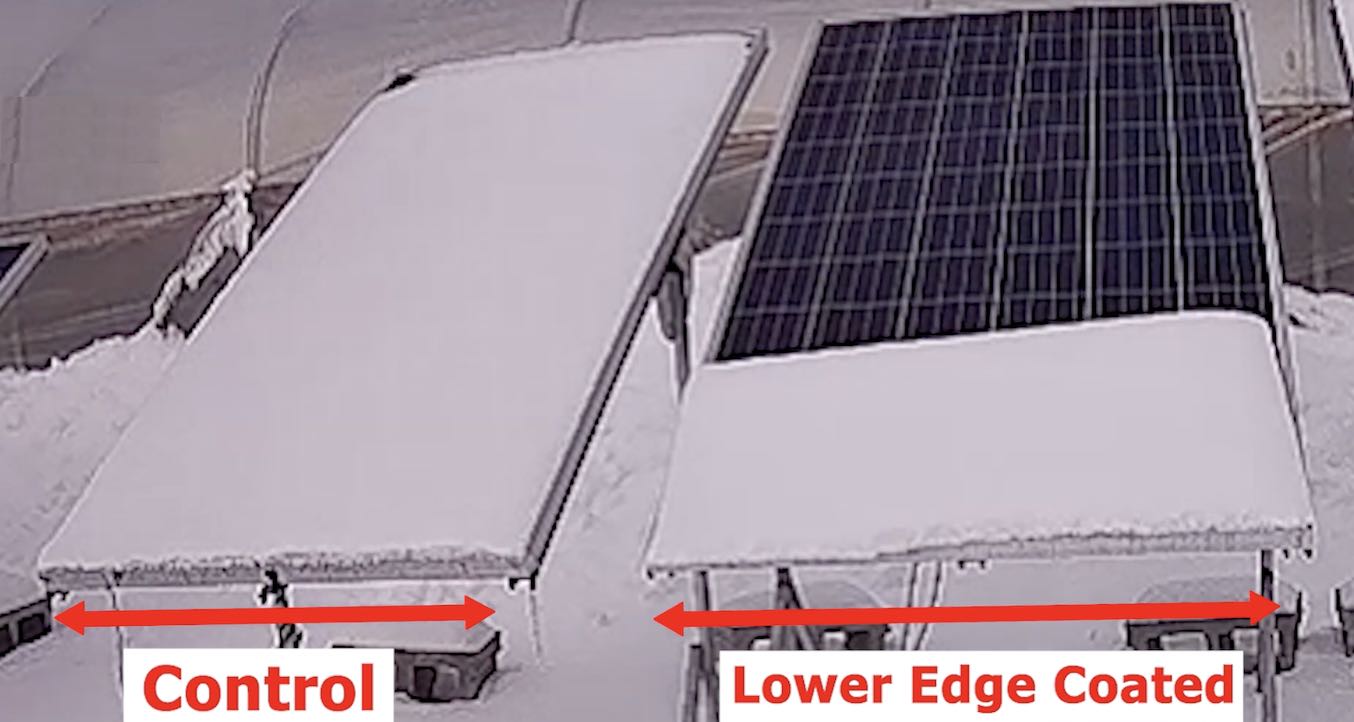

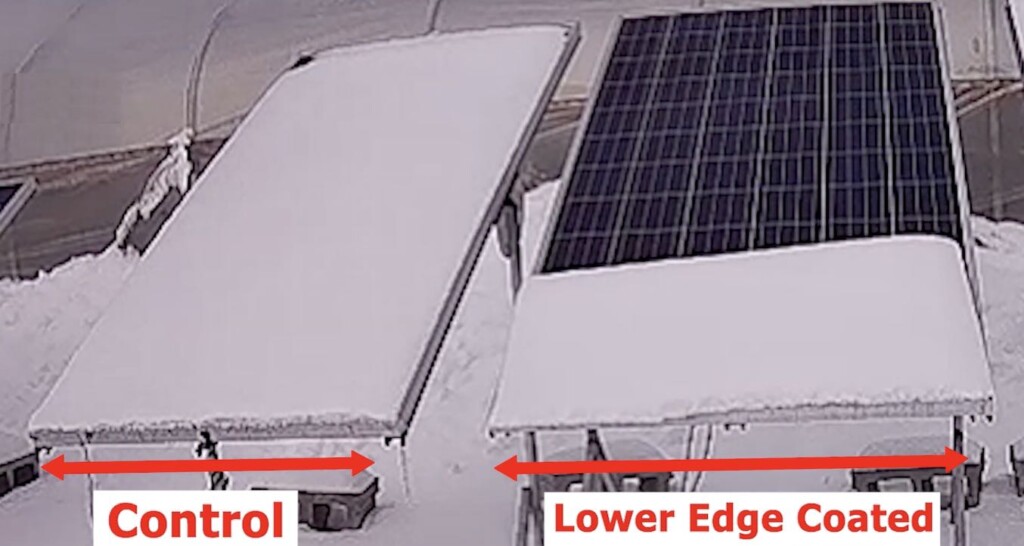

The product is a novel strip that is applied to only the lower edge of the panel, which causes the melting of the snow without interfering with the absorption of sunlight.

In a video demonstrating Snow-Free Solar, the Ohio innovators say the easy-to-apply strip “does not cause any partial shading or hot spots on the panel and does not invalidate module warranty.” It can, in fact, improve the life expectancy of the panels.

The flexible strip doesn’t require any energy to operate and the coatings are “extremely durable, strongly adhering to the PV.”

“There is no need for power—it is passive,” says Hossein Sojoudi, the Associate Professor and Technical Advisor who founded Snow-Free Solar. “You apply it to the lower bottom and it works from there.”

CHECK OUT All the Latest Solar Power Stories on GNN…

Super easy to install, the job can be done by unskilled labor with no training.

The company isn’t providing technical specs because of ongoing competition in the field, but, so far, “no known failure mode (has) yet to be identified” over several winters of rigorous durability tests conducted by a solar photovoltaic testing laboratory.

“We also showed that our strip coatings are durable during regular cleaning of solar panels.

“Through strategic partnerships, we demonstrated scalable manufacturing of our product with monthly production rate of 60,000 strip coatings,” he added.

They expanded their pilot test partners to more regions and utility companies with thousands of expected installations by the end of 2023.

The data demonstrated more than 3.4% and 5.1% annual improvement in power generation in Massachusetts and Japan respectively.

With additional direct sales to pilot test partners and a payback time of 2 years, they estimate to reach a production rate of 1 million strip coatings by the end of 2024.

“Our solution is a game-changing technology,” said their business adviser Dan Vining.

They will use funds won in the American Made Solar Prize to hire new talent and continue their efforts to reach 28 million utility scale panels in the eleven U.S. states with heavy snowfall.

WOAH: Car Makes Record-Breaking 621-Mile Trip on Single Charge Powered by the Sun

That may lead to an additional $150 million in annual revenue—commercializing their product to “deliver on the promise of solar energy all year long.”

SHINE A LIGHT on This Upcoming Solution With Solar-Lovers on Social Media!