Along with routinely launching robots across the final frontier, NASA is also involved in sustainable aviation research, and this division may have cracked the code to creating a lighter, safer battery back with multiple times more discharge power than lithium-ion batteries.

Lithium-ion batteries, the current industry standard for electric vehicles, contain liquids that make them vulnerable to overheating, fire, and loss of charge over time. By contrast, NASA’s SABERS (Solid-state Architecture Batteries for Enhanced Rechargeability and Safety) project is developing experimental solid-state battery packs that do not suffer from these drawbacks.

SABERS receives funding from NASA’s Convergent Aeronautics Solutions project, which is designed to investigate certain technologies to solve aviation’s biggest challenges: in this case, battery-powered flight.

Carbon from air travel equates to around 2% of all global greenhouse gas emissions. Batteries are hypothesized as a potential ameliorating solution to emissions-heavy jet fuel.

During the past year, SABERS’ solid-state batteries have been honed to produce a discharge rate much higher than any other example on the market by a factor of 10—and then again by a factor of 5.

Inside the battery, sulfur and selenium cells stacked directly on top of one another without casings allow for greater weight savings. Along with the cells themselves, multiple batteries can be stacked without any separation between them.

“Not only does this design eliminate 30 to 40 percent of the battery’s weight, it also allows us to double or even triple the energy it can store, far exceeding the capabilities of lithium-ion batteries that are considered to be the state of the art,” said Rocco Viggiano, principal investigator for SABERS at NASA’s Glenn Research Center in Cleveland.

ATTEMPTS TO DECARBONIZE FLYING: World’s First Electric Aircraft Flight Powered by New Liquid Hydrogen–Flew for 3 Hours

It has so far allowed the SABERS team to power objects at 500 watt-hours per kilogram–double that of an electric car.

This year, the main objective for SABERS was to show the battery’s properties meet its energy and safety targets while also demonstrating it can safely operate under realistic conditions and at maximum power, NASA writes.

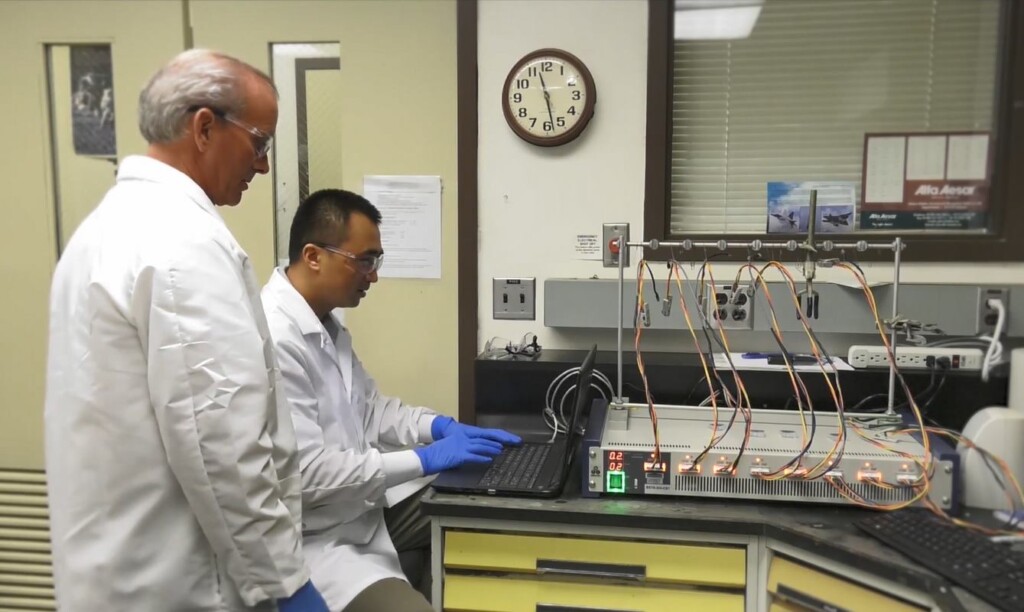

Partnering with Georgia Tech, SABERS has been able to use different methodologies in their work which has so far benefitted the batteries.

MORE BATTERY BREAKTHROUGHS: The Biggest EV Battery Recycling Plant Opens in the US

“Georgia Tech has a big focus on micromechanics of how the cell changes during operation. That helped us look at the pressures inside the battery, which then helped us improve the battery even more,” said Viggiano.

“It also led us to understand from a practical standpoint how to manufacture a cell like this, and it led us to some other improved design configurations,” said Viggiano.

SHARE This Big Battery News With Social Media…

I hope you guys are doing a big “high-five”!!! Bravo!